Please select your preferred language

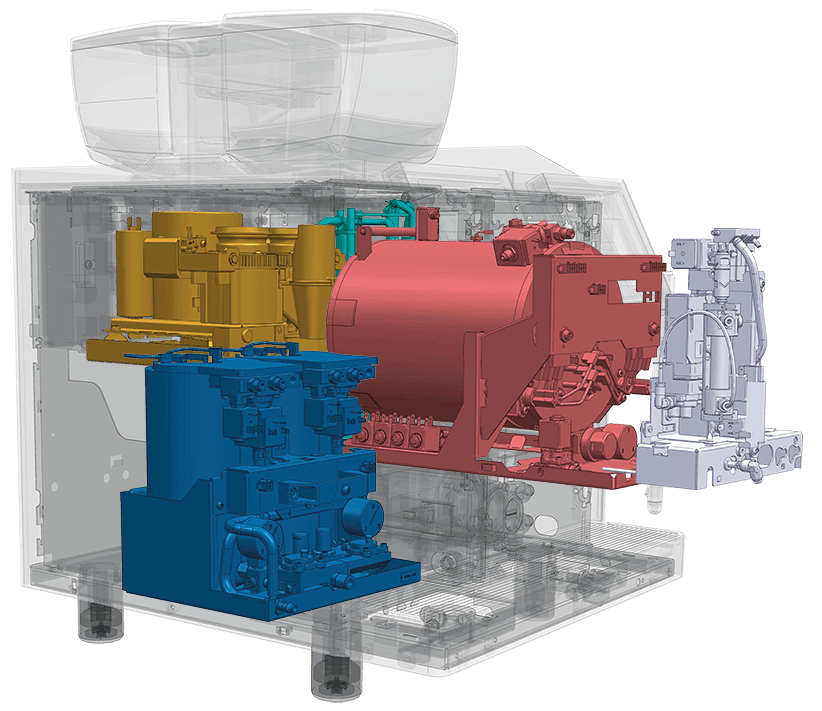

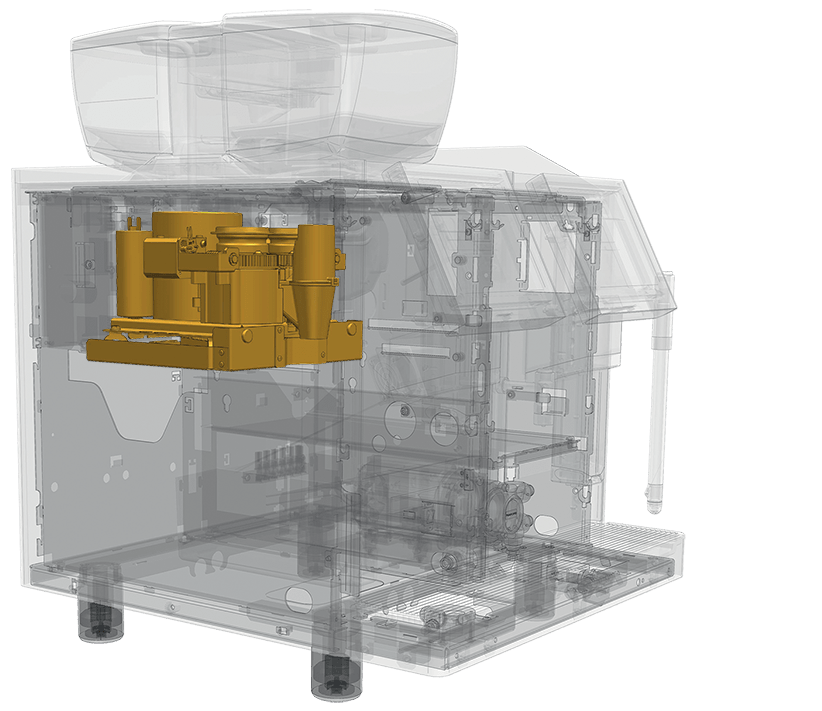

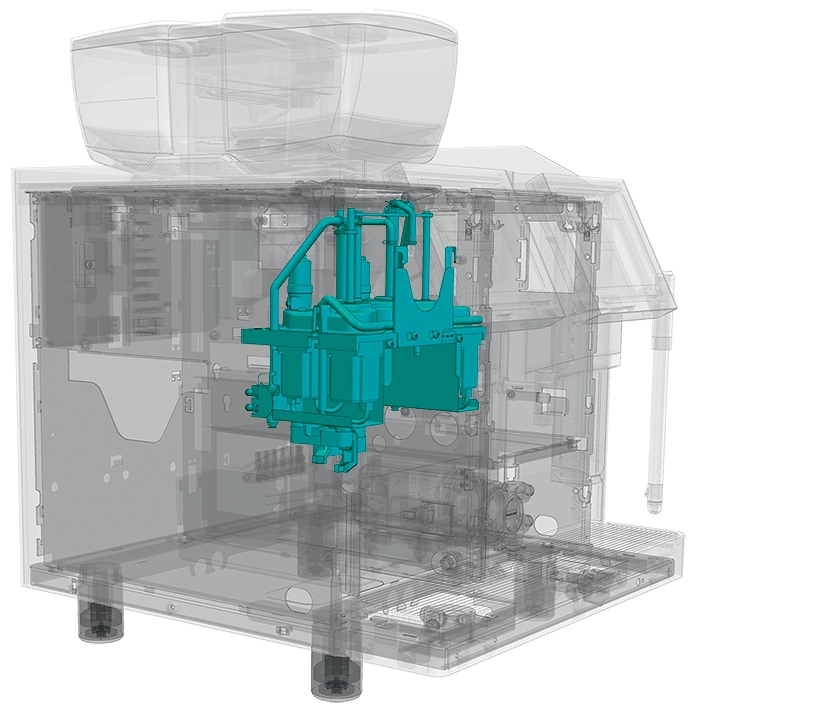

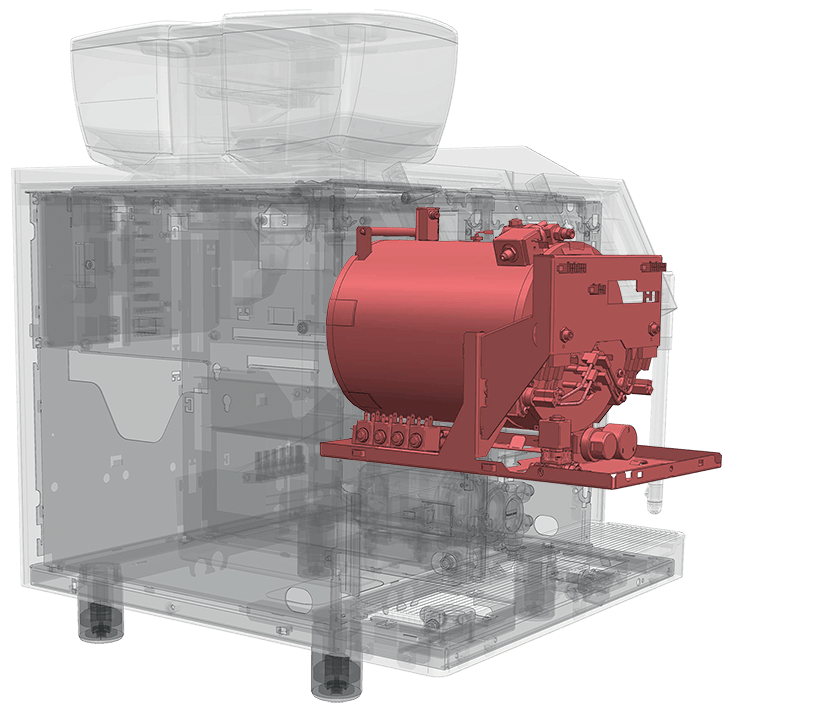

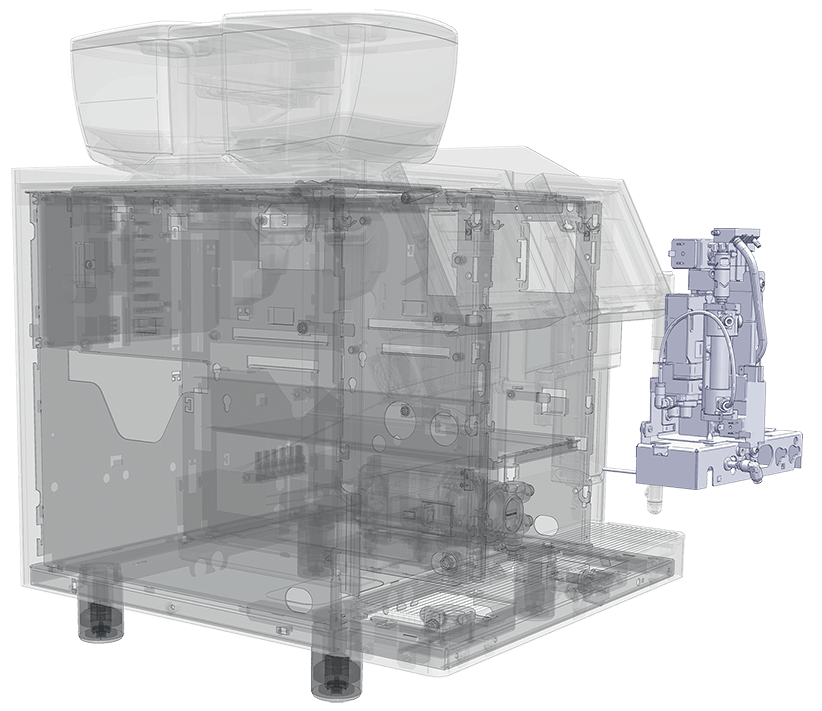

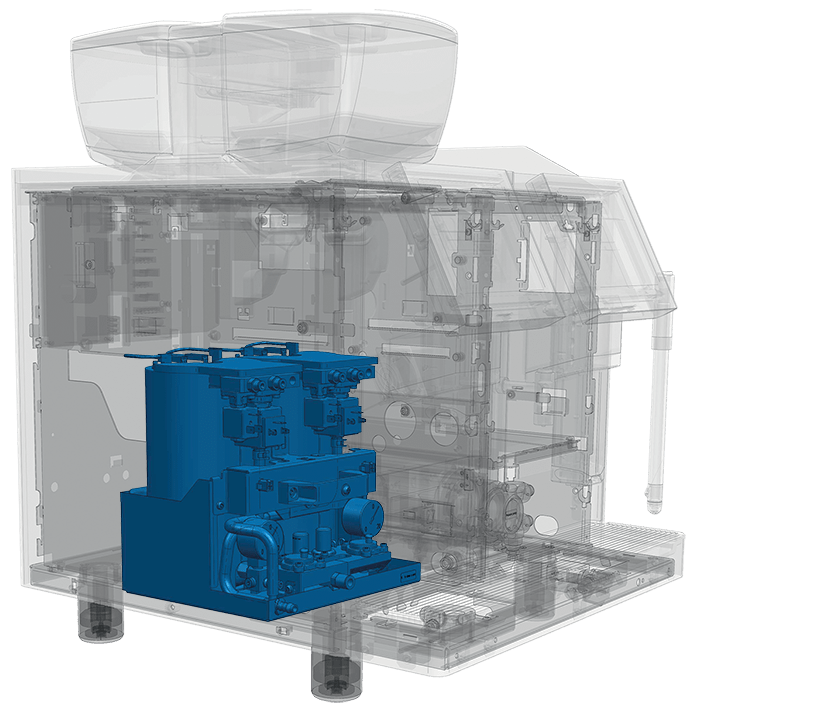

Super Traditional

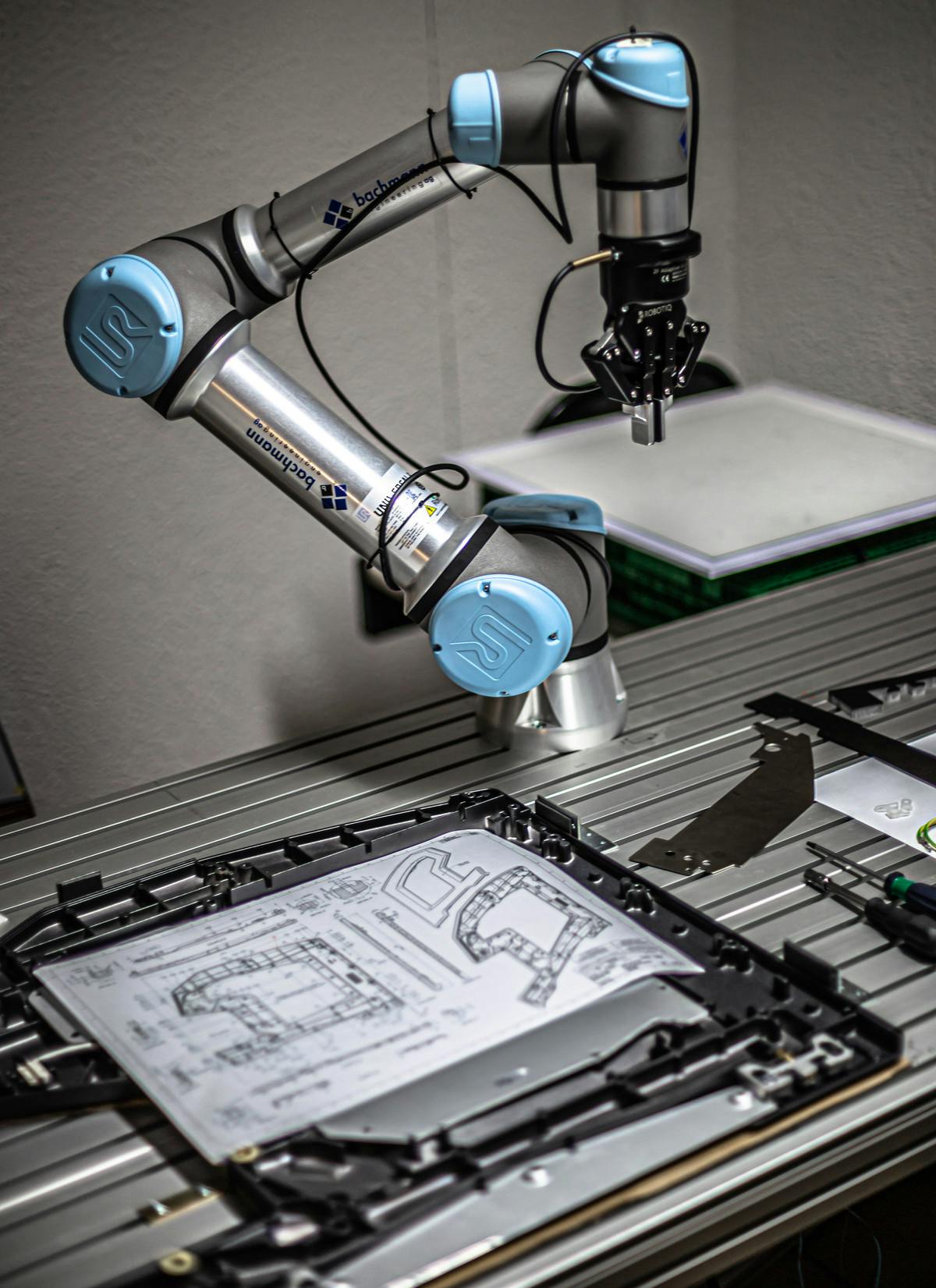

Eversys has always aimed to bridge the gap between the worlds of traditional and super-automatic machines to elevate the role of the barista to a higher level of creativity, in order to let human skills flourish.

“In many ways, Super Ts are still unexplored territory. It’ll continue to test the future of customer service, coffee quality, and consumer expectations. But the thing that will really transform this landscape, is that well-made coffee will no longer be an exclusively hand-made product. Once you realise that, the business model has to change.”. Champion Barista, Matt Perger.